MyNoke was founded in New Zealand in 2007 by a soil scientist and through continued innovation and development, is now the largest vermicomposting operation in the world by volume. To date, MyNoke has processed over 1.4 million tonnes of organic waste – waste that would have often ended up being disposed of in landfills.

Soil health is at the heart of MyNoke’s operations and as such, we have strong environmental credentials and continually invest in vermicomposting technology to maintain our position as industry leaders, tackle new organic waste streams and further benefit the environment.

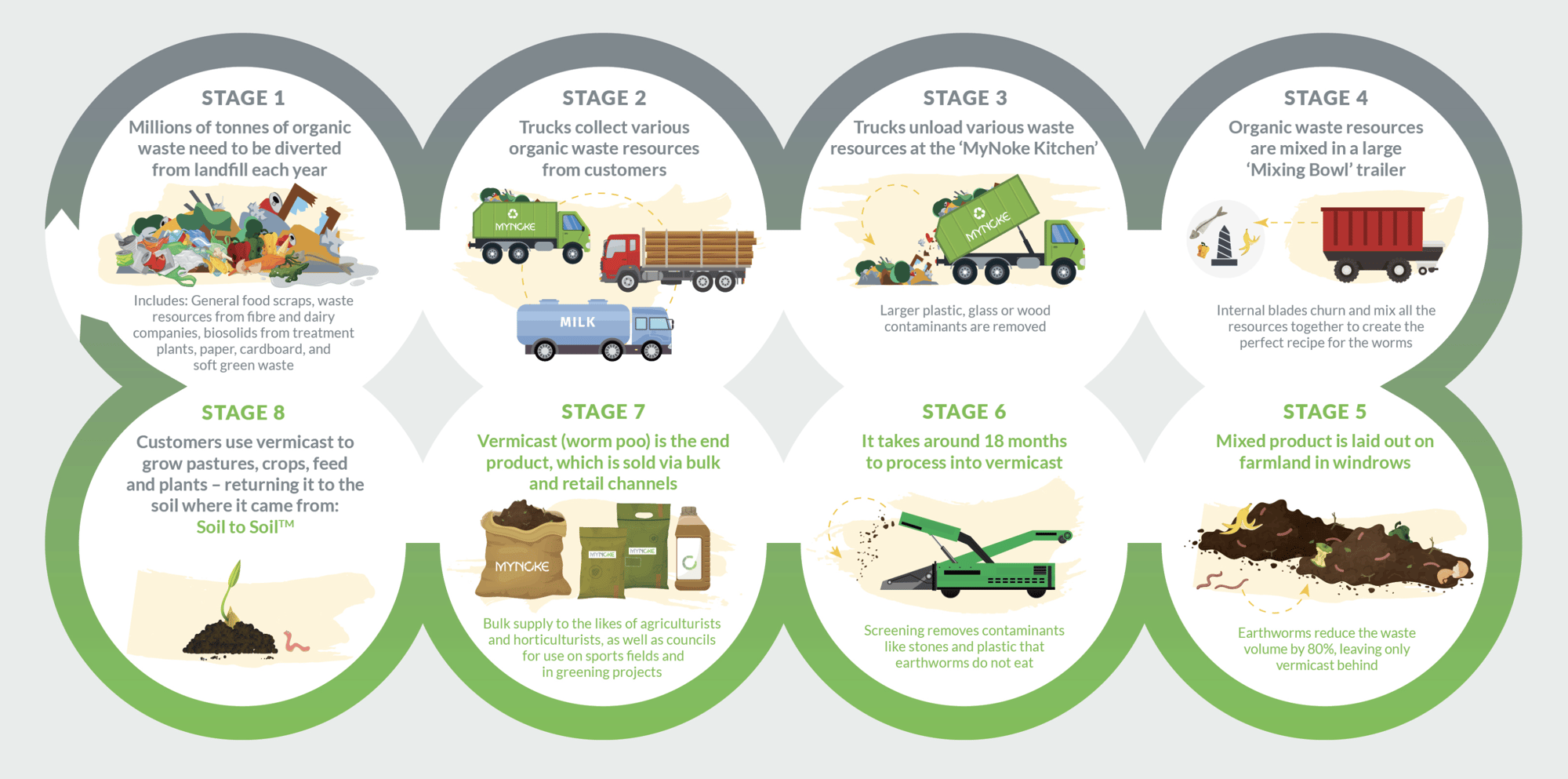

How does it work?

Organic waste materials from NZ industry and local councils, among others, are accepted at our worm farm locations, known as vermicomposting sites, where carefully managed proportions of carbon-rich wastes (paper and cardboard waste, wood, pulp mill solids, and others) are mixed with nutrient-rich organic wastes (biosolids, food waste, DAF sludge, animal skins, paunch, and others) to create the optimum ‘feedstock’ for earthworm species.

The following diagram provides an overview on our circular process. If you'd like to know if your organic waste may be suitable for our worms Contact Us to find out more.

The combination of carbon-rich and nutrient-rich waste sources must meet three criteria:

-

Highly attractive and healthy for vermicomposting. A suitable ‘diet’ for earthworms, allowing rapid reproduction and complete consumption and stabilisation of organic waste.

-

Mitigating negative effects on people and the environment. Compliance achieved with resource consent conditions and alignment with social and cultural expectations.

-

Producing high quality earthworm products, such as vermicast and earthworms for local end users.